Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.

February 20, 2017

Enabled to shorten analysis time with increased analysis accuracy and improved

licensing system

New Delhi, February 20, 2017 --- Hitachi Industry & Control Solutions, Ltd. (President and CEO: Mitsuo Takayama; "Hitachi Industry & Control") today announced that it will begin sales of ADSTEFAN Ver. 2017, a casting simulation system, in the Republic of India, the People's Republic of China, and Southeast Asian countries in March 2017. ADSTEFAN Ver. 2017 has increased temperature analysis accuracy, product defect visualization utilizing X-ray CT imaging data, and enhanced functions to improve comparative verification accuracy. Furthermore, the analysis has been strengthened by improving the licensing system to allow the combined simultaneous execution of differential analysis and parallel calculation with multiple CPUs.

The product supports three languages: Japanese, English, and Chinese. Moving forward, Hitachi Industry & Control aims to sell 150 licenses per year.

ADSTEFAN is a casting simulation tool to predict casting defects before they occur on the front lines of casting production. It simulates the inflow of molten metal into casting molds as well as the hardening process, both of which are unseen, and visualizes the process in 3D. This enables the reduction of the number of casting prototypes, shortened development time, and improved quality, thereby demonstrating results in terms of reductions in cost and resources consumed.

Recently in the molding materials industry the convenience of CAE*1, analysis systems by computers, has attracted attention, and many companies are increasingly introducing it. Since Hitachi Industry & Control started to sell ADSTEFAN in 1999, it has aggressively enhanced the functions and improved the product performance based on customer companies' requests and the outcomes of collaborative research with academic institutions and partner companies. It has increased the convenience of CAE by providing improved versions every year, and has contributed to the development of the molding materials industry.

ADSTEFAN Ver. 2017, which will begin sales now, has increased the accuracy of the analysis of heat conduction on a contact point of casting or a mold that includes a curved surface, overlays of X-ray CT imaging data on an analysis result to enable the visualization and quantification of defective parts, and realized improvements in the comparative verification accuracy. Moreover, the licensing system has been improved to accelerate the analysis speed, by allowing the combined simultaneous execution of differential analysis and parallel calculation with multiple CPUs. It has enhanced functions to respond to market needs.

Through the promotion of ADSTEFAN, Hitachi Industry & Control will contribute to the research, design, development, and manufacturing of social infrastructures, automobiles, transport equipment, airplanes, IT, environment, and power related equipment in many countries.

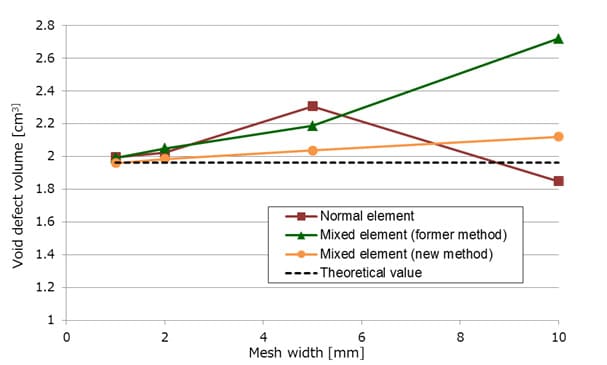

1. Highly accurate temperature analysis function adopting a new numerical analysis algorithm Applied temperature analysis solver*2 for die temperature analysis and solidification analyisis, and improved evaluation accuracy of heat transfer conditions on the contact point of curved surface shaped cast and mold, the evaluation of which was difficult using the finite difference method*3. This enables temperature analysis for a rough mesh of mixed elements*4 with high accuracy in a short period of time.

Figure 1. Evaluation example of temperature analysis results adopting a new numerical analysis algorithm

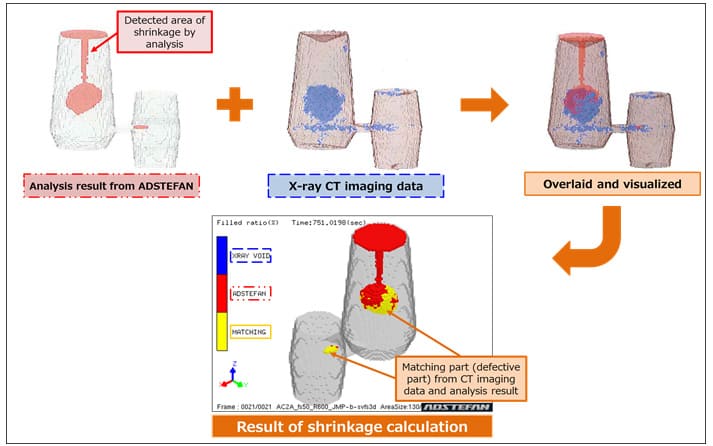

2. X-ray CT imaging data mapping tool

Shoots a product with X-ray CT imaging equipment, and extracts and visualizes void*5 defective parts such as shrinkage*6 and entrapped air*7, utilizing CT value*8 of the obtained data. This product quantifies the concordance rate by overlaying and displaying the information about defective parts extracted from image data on the analysis result in the system, which enables the improvement of comparative verification accuracy. In addition, the extracted shapes from the image data can be output as an STL*9 file.

Figure 2. Example of comparing extracted defect parts and analysis result (soundness)

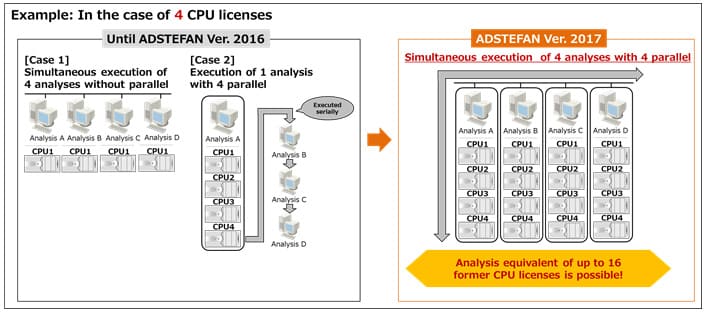

3. Utilization of license management

Allows for the efficient combined simultaneous execution of differential analysis and parallel calculation with multiple CPUs, and shortens analysis time for design work.

For example, in the past if you had four CPU licenses, you were formally able to perform analysis with only four CPUs. With ADSTEFAN Ver. 2017, you can use four CPUs concurrently on four personal computers, which allows for analysis with up to 16 CPUs with four CPU licenses.

Figure 3. Improvement in licensing system

- "ADSTEFAN" is a registered trademark of Hitachi Industry & Control Solutions, Ltd.

- When exporting this product, please carry out all required procedures after confirming all restrictions (for example, Japan's Foreign Exchange and Foreign Trade Law, and American export control laws and regulations).

*1 CAE (Computer Aided Engineering): The advanced consideration supports utilizing computer technology for product design, manufacturing, etc.

*2 Solver: A simulation program.

*3 Finite difference method: A calculation method using mesh piled up with cubes and cuboids.

*4 Mixed element: An element for which different material information is to be considered.

*5 Void: A cavity.

*6 Shrinkage: A cavity area generated by solidification contraction during the hardening process of molten metal that is filled in a mold.

*7 Entrapped air: A part that entrains air during the inflow of molten metal.

*8 CT value: The thickness value in CT images.

*9 STL (Standard Triangulated Language): A file format for saving three dimensional models.

Hitachi, Ltd. (TSE: 6501), headquartered in Tokyo, Japan, delivers innovations that answer society's challenges. The company's consolidated revenues for fiscal 2015 (ended March 31, 2016) totaled 10,034.3 billion yen ($88.8 billion). The Hitachi Group is a global leader in the Social Innovation Business, and it has approximately 335,000 employees worldwide. Through collaborative creation, Hitachi is providing solutions to customers in a broad range of sectors, including Power / Energy, Industry / Distribution / Water, Urban Development, and Finance / Government & Public / Healthcare. For more information on Hitachi, please visit the company's website at http://www.hitachi.com.