Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.

March 06, 2018

Enhanced functions aimed at improving fluid flow analysis, shortening solidification analysis time, and improving operability

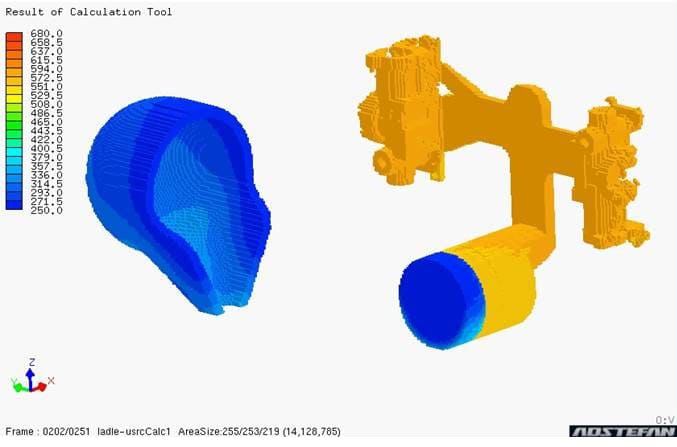

Example of high pressure die casting simulation using moving body consideration function for fluid flow analysis

Tokyo, March 6, 2018 --- Hitachi Industry & Control Solutions, Ltd. (“Hitachi Industry & Control”) today announced that it will begin sales of ADSTEFAN Ver. 2018, a casting simulation system with enhanced functions aimed at improving fluid flow (1) analysis, shortening solidification analysis time and improving operability, in Japan, India, the People's Republic of China, and Southeast Asian countries. ADSTEFAN Ver. 2018 supports three languages: Japanese, English, and Chinese, and Hitachi Industry & Control aims to sell 150 licenses per year for the research, design, development, and manufacturing of social infrastructures, automobiles, and transport equipment both in Japan and overseas.

ADSTEFAN is a casting simulation tool to predict casting defects before they occur on the front lines of casting production. It simulates the inflow of molten metal into casting molds as well as the hardening process, both of which are unseen, and visualizes the process in 3D. This enables the reduction of the number of casting prototypes, shortened development time, and improved quality, thereby demonstrating results in terms of reductions in cost and resources consumed. Since Hitachi Industry & Control started to sell ADSTEFAN in 1999, it has aggressively enhanced the functions and improved the product performance based not only on customer companies' requests but also on the outcomes of collaborative research with academic institutions and partner companies, and it has provided improved versions every year.

In recent years, in many industries including the automotive and transport equipment industries and the infrastructure industry, the development of new products to meet diverse needs is picking up pace. As a result, product parts need to be more complex in shape, more lightweight and durable and delivered within a shorter time frame and at lower cost, and there have also been requests for further improvement of analysis precision and improvement of work efficiency in the casting simulation process.

In light of these needs, ADSTEFAN Ver. 2018, which will go on sale now, has enhanced functions aimed at improving fluid flow analysis, shortening solidification analysis time and improving operability, which were improvements commonly requested by user companies. Through the continuous improvement and sales expansion of ADSTEFAN, Hitachi Industry & Control will contribute to the development of the casting industry and the development of industry worldwide.

(1) Fluid flow: the way molten metal flows when injected into a mold

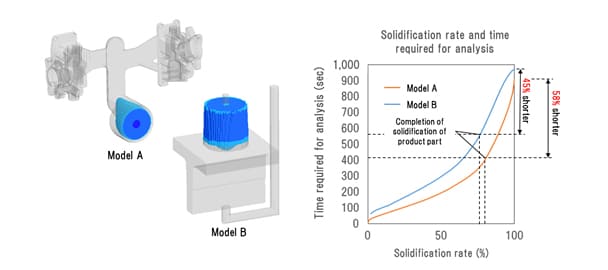

Relationship between solidification rate and time required for analysis with enhanced solidification rate control function

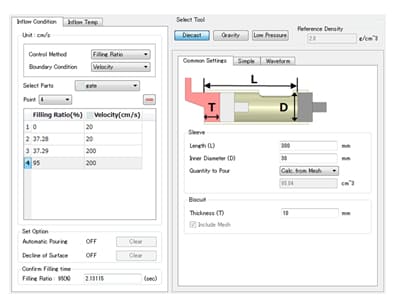

Screen for inflow condition settings (example of high pressure die casting)

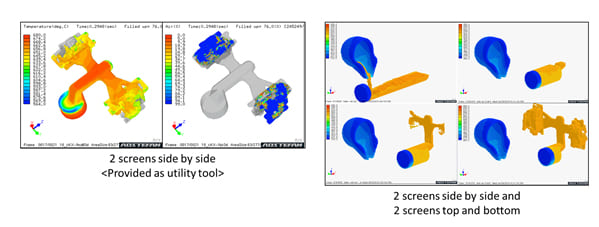

Example of Analysis Results Display

(2), (3): A ladle and a plunger tip are used to push molten metal into molds during high pressure die casting (one of the die casting techniques).

(4) A stopper is used to plug the cavity during the stopper pouring process (process of pouring molten metal into molds) of gravity die casting (one of the die casting techniques).

Website about ADSTEFAN Ver.2018

http://www.adstefan.com/english/index.html

Notes

Hitachi Industry & Control, headquarter in Tokyo, Japan, is a major company supporting the Hitachi group’s industrial solution business. The company has provided solutions to a wide range of fields including industrial, security and embedded system. Unite individual products and technologies from an optimum point of view, find and solve customer challenges together. In embedded system development for automotive, provide engineering services for image sensing, signal processing and software development. For more information on Hitachi Industry & Control, please visit http://info.hitachi-ics.co.jp/eng/index.html.

ProSIM R&D Pvt. Ltd.

#4, 1st 'B' main, 1st 'N' Block Rajajinagar, Bangalore - 560 010, India

TEL:+91-80-2332-3020 FAX:+91-80-2332-3304

KADKRAFT SYSTEMS Pvt. Ltd.

SCO 196-197, 1st Floor, Sector 34-A, Chandigarh, 160022, India

TEL:+91-172-266-1311, +91-90231-72022, +91-98140-21311

FAX:+91-172-260-2557