The casting process is used to create complex metal parts with ease, irrespective of their sizes. The molten metal fills up a mold, then it cools down and solidifies into the desired shape; thus, a casting is formed. In the absence of appropriate designs and production conditions, failure rates skyrocket as yield rates plunge, and the entire foundry falters.

In India, resourcefulness and technological advancements are massively transforming today’s metal casting industry. Multiple CAE (Computer-Aided Engineering) technologies have been developed according to various industry needs for efficiency, quality, and productivity. To facilitate seamless casting designs with minimal predictable defects, simulation software like ADSTEFAN is specially designed to enable the fast and uninterrupted set-up of a project and productions, even with large or complex casting parts.

ADSTEFAN’s superior casting solutions help foundries to arrest casting defects, optimise product designs, reduce re-work and rejections and improve yield.

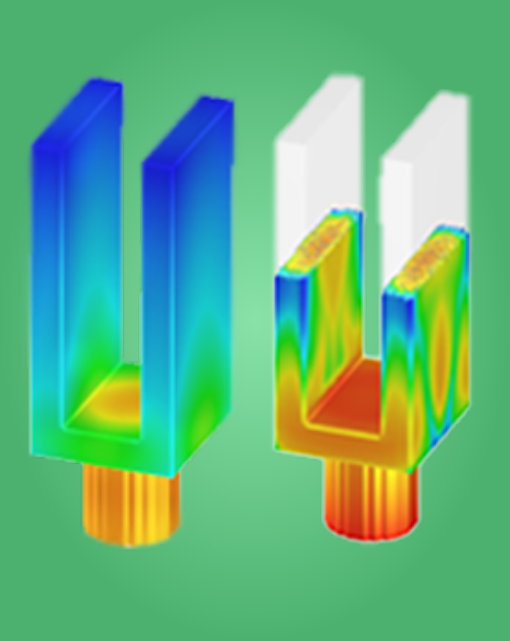

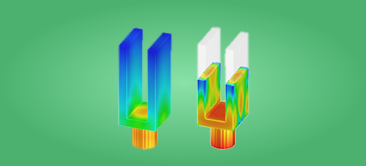

High-Pressure Die casting (HPDC) is a versatile casting process, where the high-pressure metal liquid is injected into a metal die cavity at high speed so that the metal liquid solidifies after cooling down to form a casting. This process is used to create different types of products like automobile parts, home appliance parts, decorative hardware, and many other components.

ADSTEFAN’s smart high pressure die casting simulation helps casting engineers predict casting defects, thereby reducing secondary operations and facilitating process optimisation.

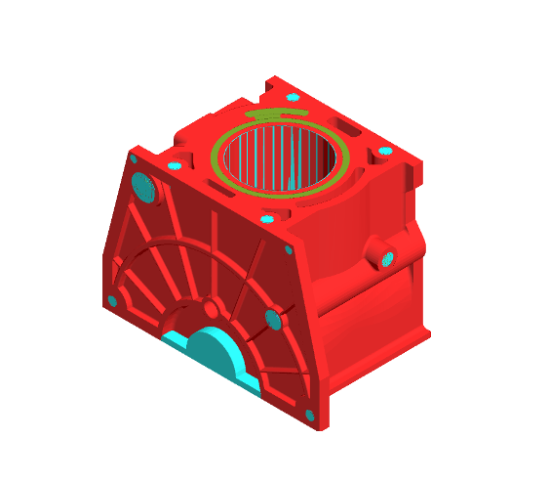

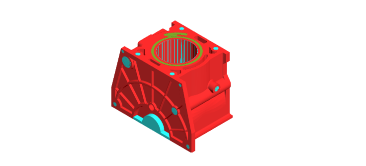

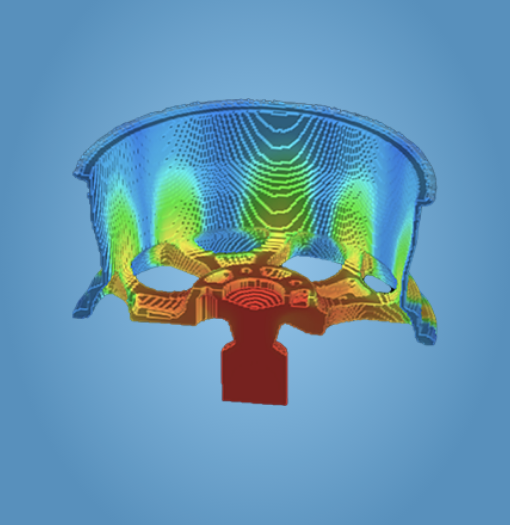

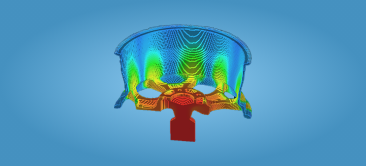

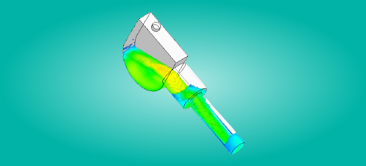

Sand casting is different from die casting in the way that molten metal arrives in the mold – while in HPDC, the molten metal is injected into the mold under high pressures, sand casting uses only gravitational force to pour the molten metal into the mold without any external pressure. ADSTEFAN's superior sand casting solutions help industries to adopt casting simulation to predict casting defects and optimise designs for various complex casting production, which include automotive parts like engine cylinder heads, turbos, brake calipers, and steering knuckles as well as kitchen tools.

In Low-Pressure Die Casting (LPDC), pressurised air is used to fill a die cavity with molten metal from a holding furnace positioned in the lower part of the vertical die casting machines. LPDC process is often used to manufacture automotive and non-automotive parts. ADSTEFAN’s state-of-art LPDC module provides a special user interface that makes simulation quicker or more precise by omitting the meshing of the stalk and holding furnace and thus saving the computer resources.

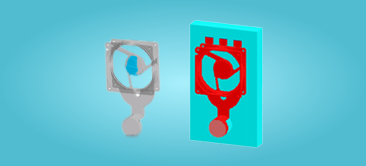

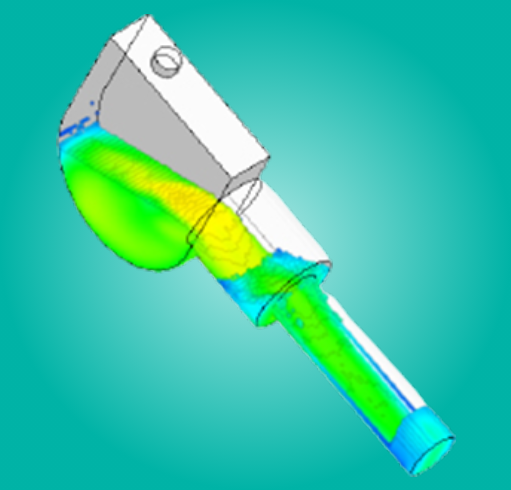

ADSTEFAN’s tilt casting module entails an intuitive modelling environment that is specially designed to help casting engineers effectively model tilt casting applications. ADSTEFAN’s tilt casting module also facilitates enhanced production capabilities and higher product quality by predicting defect potentials at a design stage.

We are here to help you.

Contact Us