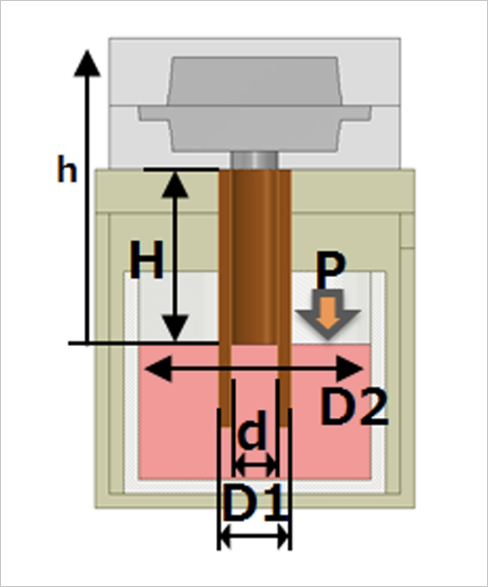

Low-Pressure Die Casting (LPDC) involves filling a permanent mould with molten metal upward from a pressurized furnace located below the mould via a runner or a stalk. ADSTEFAN renders casting simulation at LPDC foundries and tool shops either efficient or precise depending on their varied needs.

Efficiency and precision of ADSTEFAN’s Low-Pressure Die Casting module are made possible by its special user interface where users can skip the meshing of holding furnaces and stalks. A holding furnace and a stalk are positioned at the bottom of LPDC machines and provide the mould with molten metal.

By omitting the meshing of holding furnaces and stalks, ADSTEFAN users foundries can free up computer resources and run a quick and efficient simulation. Alternatively, if the users allocate the freed-up computer resources to areas other than the holding furnaces and stalks to increase the number of meshes in those other areas, then simulations can be made more precise and accurate.

In addition to the aforesaid basic LPDC module, ADSTEFAN’s Advanced Defect Prediction Tool (ADPT) also serves the efficiency and precision of Low Pressure Die Casting simulation. ADPT adopts machine learning technology to offer more accurate and practical prediction models for shrinkage, misruns, cold shuts, and other defects than performs conventional simulation by training the machine learning tool with the shop-floor data. Based on the physical phenomenon fed on ADSTEFAN, ADPT predicts the probability of casting defects. The efficiency and precision of the ADPT extend to such an extent that its defect prediction database systematically retains the shop-floor experiences and feeds them back to future simulations.

As India’s casting industry is growing rapidly, the demand for experienced casting engineers always exceeds the supply. Under the circumstances, many foundries and tool shops are keen to do more with less and to retain and fully utilise their existing design expertise.

Casting simulation software ADSTEFAN helps foundries and tool shops to build a robust LPDC process that minimises physical prototyping, design iterations, and defect containment by predicting defects early on in the development stage and helps them to get it right the first time itself. ADSTEFAN’s ADPT also offers a platform on which foundries and tool shops systematically retain their experiences on defects and test results on defect prediction database and feedback such experiences to future simulations. ADSTEFAN assists in surviving this challenging industry where talent is a scarce resource.

We are here to help you.

Contact Us