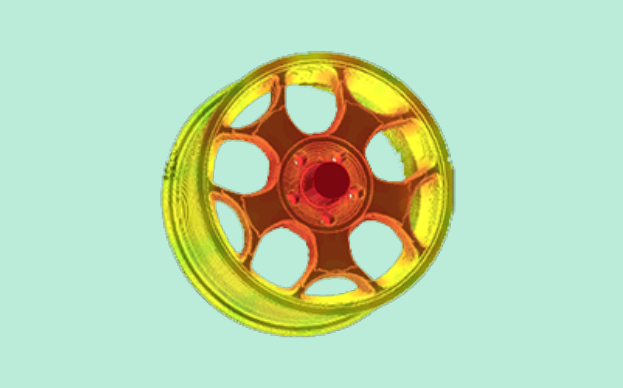

Casting simulation software, ADSTEFAN is the casting engineer’s guide to designing virtual prototypes. ADSTEFAN versatile products portfolio and featured functionalities help design and manufacturing companies to expand their modeling objectives.

The product development paradigm in today’s casting industries has shifted from traditional trial-and-error in the industrial workshop to tech-enabled simulation by the computer. Casting process simulation software like ADSTEFAN is always evolving to create new value to facilitate seamless simulation in casting design. Our array of smart processes helps to optimise product designs and production conditions for higher quality and enhanced productivity.

Learn More

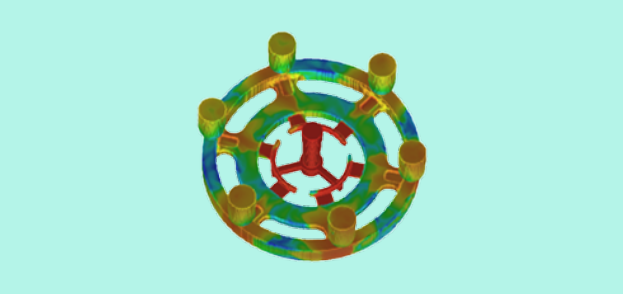

ADSTEFAN’s die casting process effectively helps to reduce secondary operations and lower costs consequently.

Learn More

ADSTEFAN's superior gravity die-casting solutions enable industries to adopt casting simulation to enjoy multiple benefits like the prediction of casting defects and optimizing designs.

Learn More

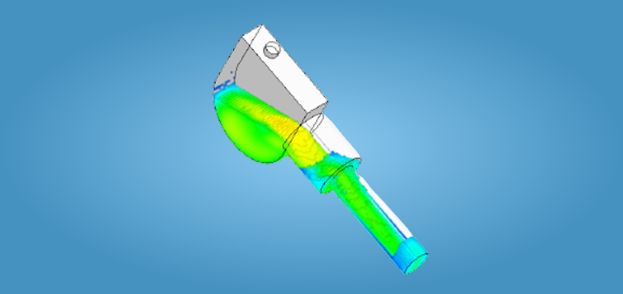

ADSTEFAN’s outstanding low pressure die casting simulation helps to simulate fluid flow and solidification efficiently without meshing stalks and holding furnaces.

Learn More

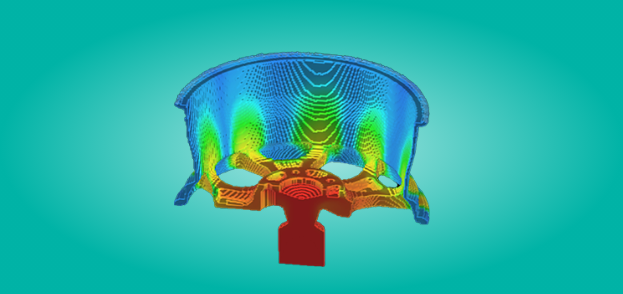

ADSTEFAN’s automated tilt casting module also facilitates to enhanced production capabilities and higher product -quality by predicting defect potentials at a design stage.

Learn MoreWe offer an extensive collection of foundry methodologies to meet today’s requirements.

Learn More

ADPT, ADSTEFAN’s defect prediction tool uses actual casting defect information and analysis results to build a defect prediction database using machine learning to generate the defect prediction model.

Learn More

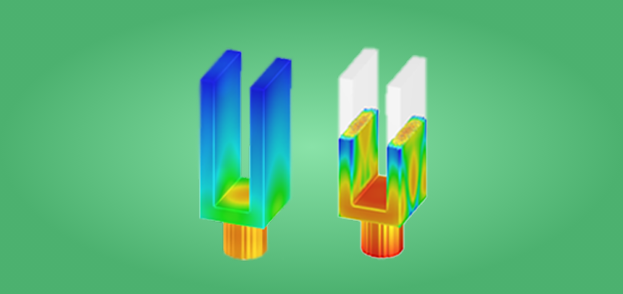

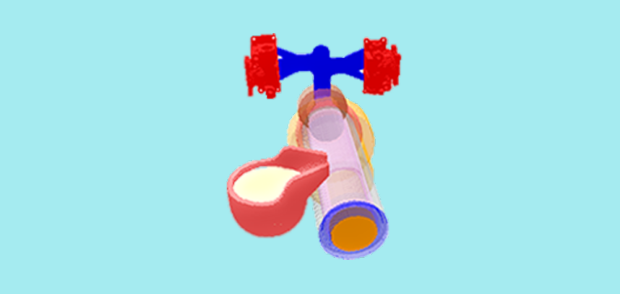

"Moving Object" functionality enables the movement of rigid bodies like ladles and plunger in pouring and injecting molten metal. This functionality enhance analysis accuracy because it contemplates how these movements affect fluid flow behavours and molten metal temperature.

Learn More

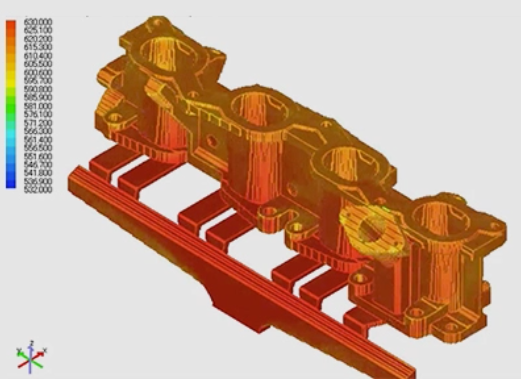

CSM is thermal analysis method that can predict the die temperature at a cyclic steady state without a repeated numerical calculation.

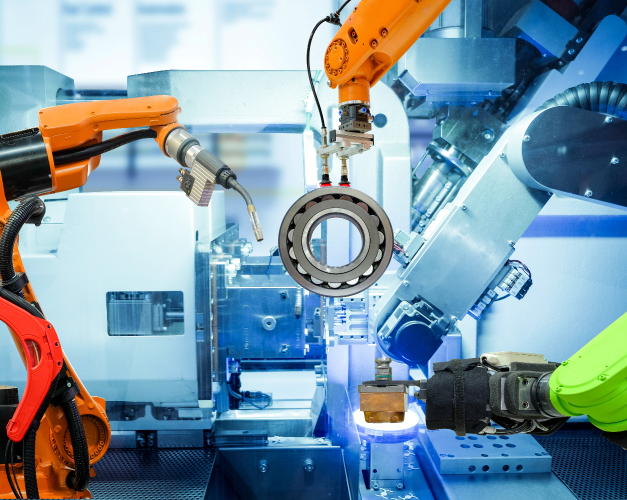

Learn MoreWe endeavor to contribute to myriad industries via our manufacturing and creative technological strength to deliver value.

We are here to help you.

Contact Us