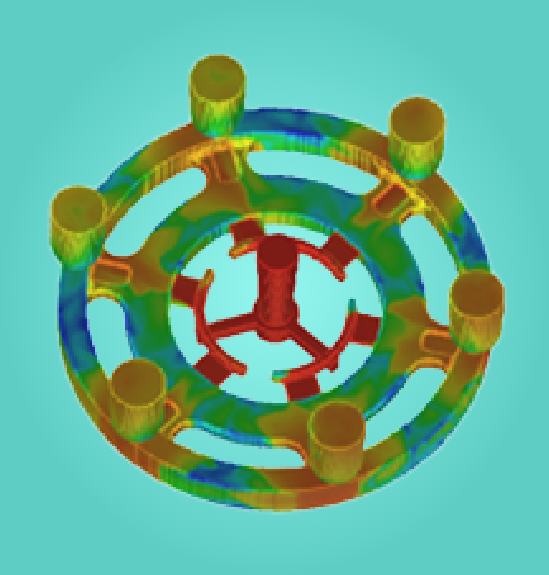

Casting simulation software, ADSTEFAN offers an accurate and affordable casting simulation environment that is focused on creating high-quality components along with a highly intuitive user experience. Through virtual prototyping, it helps Indian product designers and foundry engineers to visualize casting defects like air entrapment and shrinkage porosity right from the early design phase and rectifies them, thus avoiding costly downstream corrections later.

ADSTEFAN’s extensive collection of foundry methodologies meets today’s requirements and helps companies across industry verticals in India to expand their modelling objectives.

Advanced Defect Prediction Tool is ADSTEFAN’s unique defect prediction tool that uses actual casting defect information and analysis results to build a defect prediction database using machine learning to generate the defect prediction model.

ADPT provides a smart system for incorporating actual defect information into projects and utilizes it for the next defect prediction.

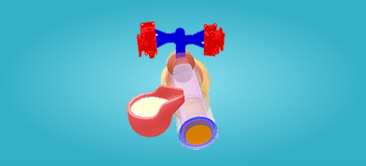

Moving Object functionality enables the movement of rigid objects like ladle pouring and plunger movement in High Pressure Die Casting. It affects fluid flow movement and molten metal temperature, thereby ensuring analysis accuracy.

By simulating moving object which affects fluid flow movement and molten metal temperature, ADSTEFAN helps in achieving analysis accuracy.

The trace of the temperature variation of a die usually shows up with a cyclic steady state after about 10 cycles. The Cyclic Steady heat balance method (CSM) is a new thermal analysis method that can predict the die temperature at a cyclic steady state without a repeated numerical calculation.

CSM is a unique component of ADSTEFAN that is used for a quick determination of the cyclic steady temperature distribution in die-casting.

We are here to help you.

Contact Us