Modern foundries use advanced computer-aided technologies and casting process modelling to facilitate casting process simulation. This provides valuable information to foundry engineers early in the product development stage and considerably reduces the time between the concept and production stage in the component lifecycle. See how the Pune-based forging giant Bharat Forge achieved First Time Quality Target and started delivering porosity-free components with ADSTEFAN, as narrated by Mr. Vipul Shah, Business Unit Head and Mr. Sasi Ramakrishnan, AVP, Engineering & Development at Bharat Forge Limited for Centre of Lightweighting Technologies.

Bharat Forge Limited has set up the Centre of Lightweighting Technologies with a capacity of 3,600 tonnes per year and aims to gradually ramp up to 36,000 tonnes per year. It aspires to be the global leader in the field of Centre of Lightweighting Technologies. The centre of excellence for lightweighting delivers end-to-end innovative solutions by using a combination of forging, casting, and other metal-forming processes.

In today’s new engineering era, the dynamics of customer expectations is to get good products for First Time Right along with porosity-free components. The biggest challenge that Bharat Forge faced was to achieve zero porosity components as the porosity issues led to rejections after machining, thus hindering customer requirement of a shorter time to market. The business experts realized that only a high-standard simulation software would help to arrest these issues by analysing the problems and imparting a faster lead time to market - that’s when the company turned to Hitachi’s ADSTEFAN and leveraged its full potential.

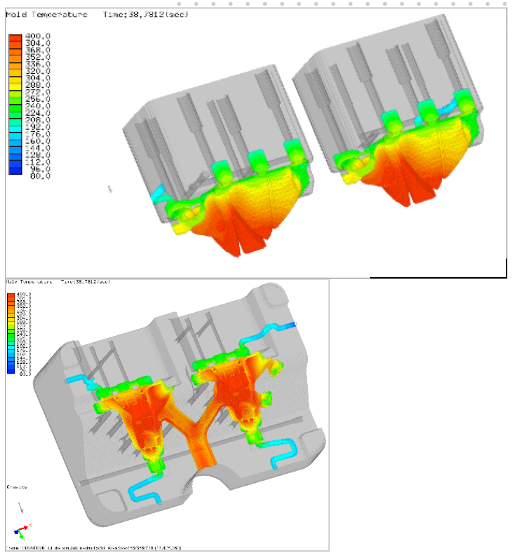

To experience better quality casting and achieve the First Time Right approach of its products, Bharat Forge Limited leveraged ADSTEFAN with Hitachi’s phenomenal service support to analyse myriad results such as flow simulation, flow temperature, air pressure exchange, solidification results, hot spot and die temperature. With ADSTEFAN, Bharat Forge could achieve porosity-free components and get First Time Right, which was admired by global customers.

“Non-fill, blowholes, and shrinkage porosity are the 3 major causes of rejection of components. With ADSTEFAN’s smart analysis, these could be improved by almost 99%.”

Mr. Vipul Shah, Business Unit Head at Bharat Forge Limited for Centre of Lightweighting Technologies.

“The Indian die casting industry will grow in leaps and bounds in the next 3-5 years” - Mr. Vipul Shah, Business Unit Head at Bharat Forge Limited for Centre of Lightweighting Technologies. It has immense scope for improvement in production, volumes, and efficiencies. India is soon going to become the global market and will cater to the US, Europe, and many other markets. Helping India gain momentum, Hitachi is leveraging its innovative technologies to facilitate exponential growth in the die casting industry.

We are here to help you.

Contact Us