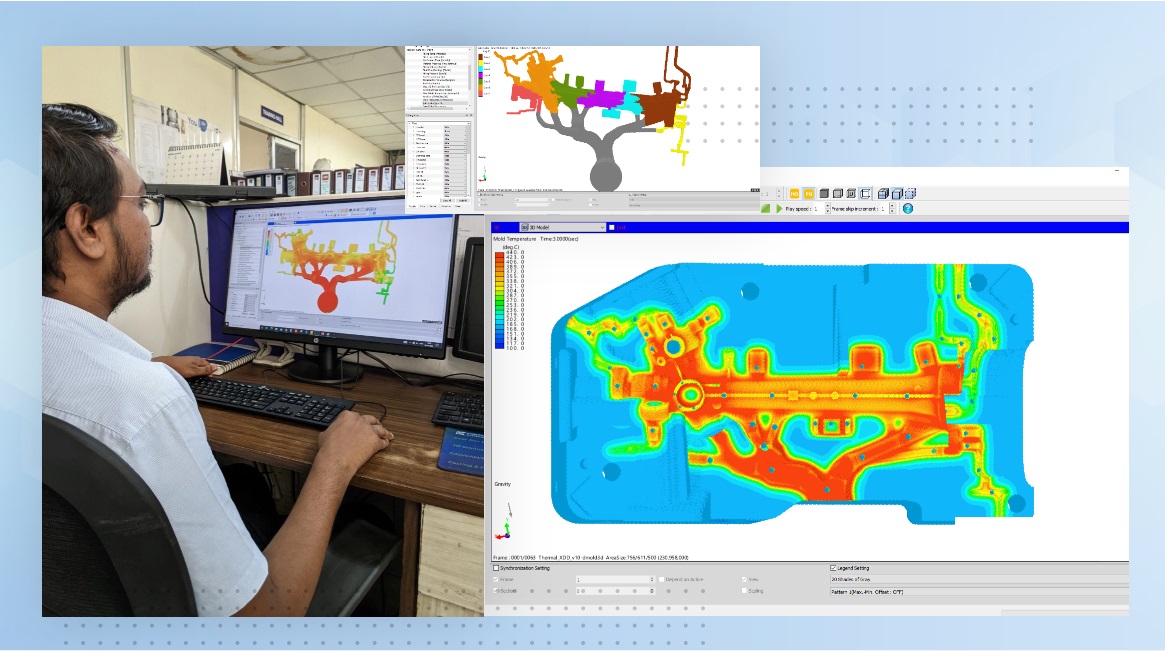

In foundries, casting processes can be improved with the help of affordable and smart simulation software, which makes the job easier for foundry engineers and owners. Rane (Madras) Limited - LMCI, an esteemed customer of ADSTEFAN and a leading auto component manufacturer, relies on ADSTEFAN to meet incredibly demanding quality targets across all its engineering processes. See how the company increased its First Time Quality Target to > 95% with ADSTEFAN, as narrated by Mr. U. Bheemaiah, GM at Rane (Madras) Ltd-LMCI.

With a practical and reliable casting simulation software ADSTEFAN, Hitachi Industry & Control Solutions Ltd. has been accompanying Indian foundries towards excellent quality for over a decade.

Recognised as a Great Place to Work, Rane (Madras) Limited regards quality as its unique value proposition to its customers and has invested heavily in quality enhancement.

To manufacture critical parts for many overseas customers, Rane (Madras) Limited wanted to introduce casting CAE (Computer-aided engineering) to usher in engineering process transformation – that’s when it turned to ADSTEFAN and leveraged its full potential. For Rane (Madras) Limited, ADSTEFAN was the best decision ever as it witnessed a real improvement in quality and then productivity –optimal casting designs based on reliable simulation, consequent seamless product launches, and hence shorter time to market. Ever since introducing ADSTEFAN, the company has been constantly upgrading its versions.

“Die casting is an emerging trend as lightweight vehicles are gaining prominence today.” – Mr. U. Bheemaiah. Following this trend, Hitachi is leveraging its casting simulation technology developed in collaboration with leading researchers to power India’s robust growth in the light metal industry and to benefit many casting engineers, ADSTEFAN users, and foundry owners. That is how the successful marriage of technology and industry collaboration forms a new future.

We are here to help you.

Contact Us